Food processing equipment Technical information

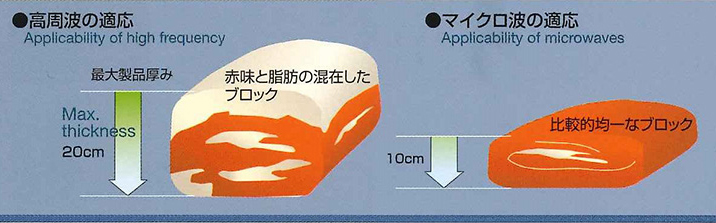

A high frequency of 13.56 MHz having a heating penetrability of several to ten and several times that of microwaves is generated. This means that thick frozen cuts containing both fat and red meat, and bulk frozen products can be processed uniformly and quickly.

Differences in Applicability of High Frequency and Microwaves

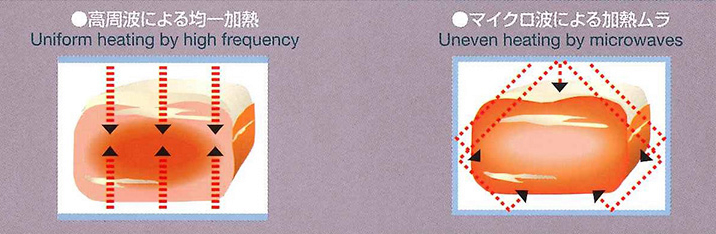

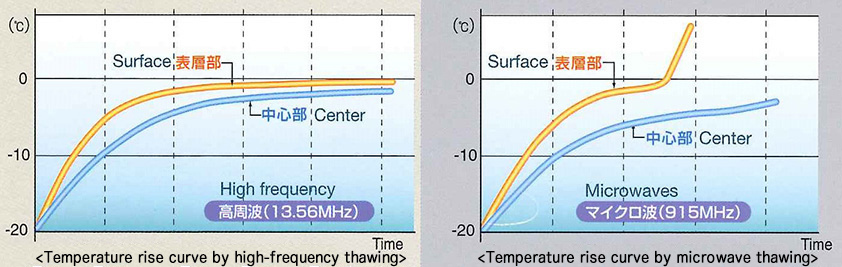

With microwave-based thawing, the temperature of water that has melted in the thawing process rises more quickly than parts of the product that are still frozen. This thawing system is disadvantageous as uneven thawing of frozen products occurs.

Whereas, with thawing by high-frequency heating, heating progresses uniformly as there is little difference in the heat generated in ice and water, and so uneven thawing does not occur.

TEMPERTRON incorporates a special high frequency circuit having particularly outstanding heating properties. This allows frozen products to be thawed uniformly and without being affected by the physical differences of products.

- With high-frequency heating, heating is uniform with little difference in heat generated in water and ice. Thawing is also uniform.

- When ice is mixed with water,heating/thawing unevenness, such as intense heating of water and even boiling, occurs.

- The temperature rise rapidly peaks at around the -5℃ to -3℃ boundary, and thawing does not proceed beyond the freezing point inside or on the surface even if heating is continued.

- The temperature of the surface rises more rapidly than the inside, resulting in thermorunaway.