Wood processing equipment Technical information

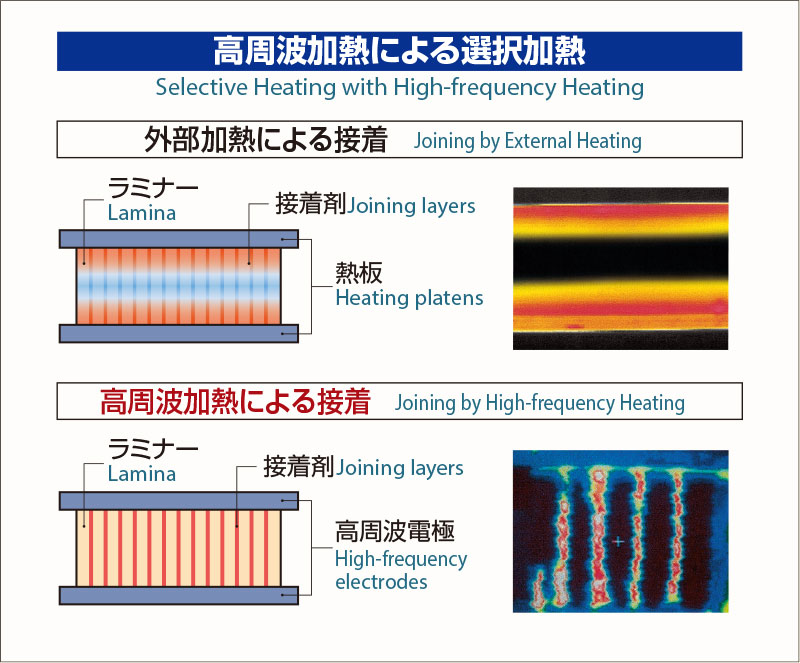

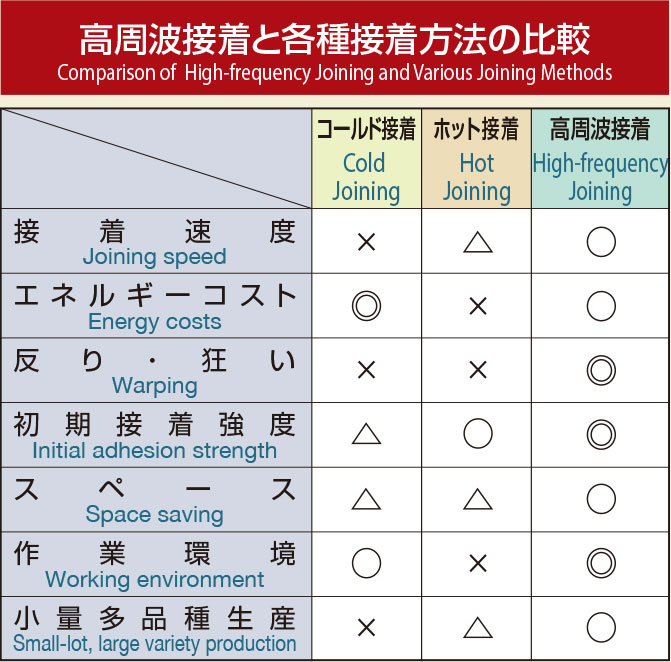

There are various methods for joining engineered wood, including the main methods of cold joining, hot joining, and high-frequency joining. High-frequency joining offers the special feature of selective heating, which heats only the adhesives, not the lumbar, resulting in a significantly shorter joining time, energy saving, and less warping after joining compared to other joining methods.

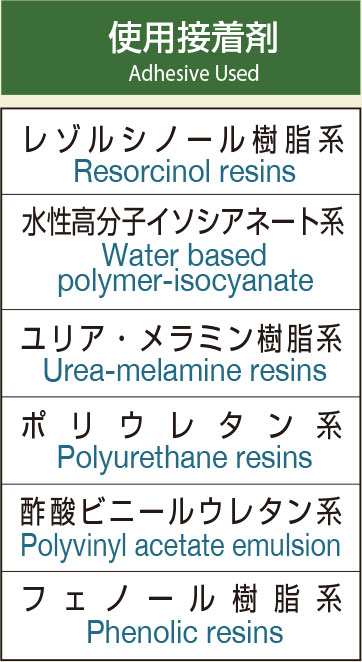

In particular, while the cold joining of resorcinol resin adhesives used with structural engineered wood and the like takes a half a day or longer, high-frequency joining of this same material can be completed in several minutes. High-frequency joining can also be applied to the various adhesives used in lumbar joining.

■Advantages of High-frequency Dielectric Heating for Lumber Joining

①Selective Heating

High-frequency dielectric heating efficiently heats the adhesives only.

②Compatible with Various Adhesives

This type of heating is compatible with the various adhesives used in lumbar joining.

③Improves Quality

The heating does not heat the lumbar and, as a result, no warping occurs.

④Energy Saving

The heating uses only the amount of energy required for joining.

⑤High-Speed Joining

Compared to a hot press, high-frequency dielectric heating significantly shortens the joining time.

Wood processing equipmentTOP [Technical information] What is wood joining by high-frequency heating? 【 What is highly efficient laminating and CLT joining by high frequency heating? │ What is highly-efficient/high-quality flush joining? │ What is adhesive joint for wooden box and paper box? │

What is high-quality siding board joining? 】│ What is hybrid kiln dryer by High-frequency heating? [Product information]