Wood processing equipment Technical information

What is high-quality siding board joining?

What is high-quality siding board joining, which increases the efficiency of gluing processes, conserves energy, and is markedly competitive?

■What are the advantages of high-frequency heating?

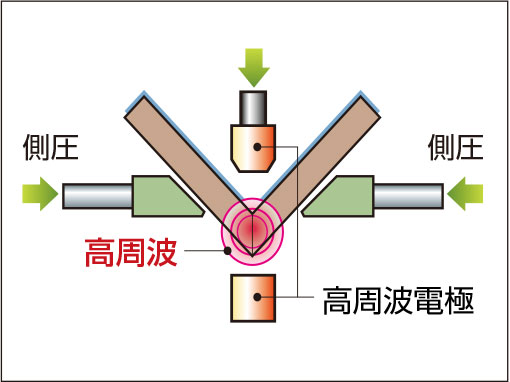

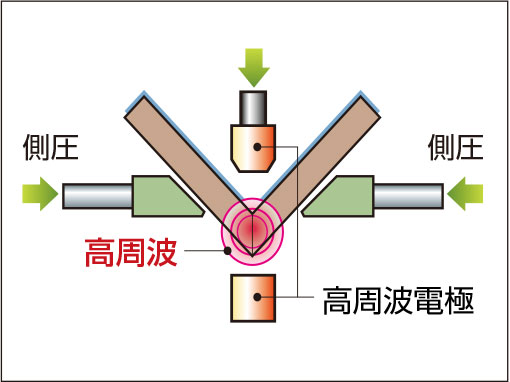

High-frequency Siding Board Joining Machine: The WALLEX series (product lineup of high-frequency ceramic exterior wall arris gluing machines) convey energy necessary for gluing to regions requiring it on an as-required basis by applying high-frequency waves directly to glue while applying pressure using air cylinders. This method saves more energy, compared to external heating methods, including far-infrared and other heating devices. It accomplishes high-quality gluing performance in a significantly short period of time without damaging the surface coating of products.

■What is the exterior-wall pre-cut method?

A required number of arrises (external corners) of the same quality can be produced using lumber remnants and wood waste cut away from window frames during the pre-cut process in the factory. The processing of wood siding is not required at a building site, which helps solve environmental problems, including noise, the dispersal of dust, and disposal of wood scrap.

The method helps build houses while taking into consideration community residents, their environments, and health in a shorter period of construction, which reduces construction costs. The exterior-wall pre-cut method is a construction system expected to become a mainstream exterior-wall ceramic construction system.

The exterior-wall precut method is a construction system expected to become the mainstream of ceramic exterior-wall construction.

Strong points of the exterior-wall precut method

- Shortening of the construction period

- Reduction of construction workers

- Reduction of material costs

- Reduction of the costs for waste disposal at sites

- A solution for environmental problems at construction sites

- Quality improvement

■High-frequency gluing

-

1. Process of width cutting

-

2. Process of beveling the edges

Cut at 44.5°

Cut at 44.5°

-

3. Starching process

The process requires only 1/3 of the glue, compared to that usually applied, which increases economic efficiency.

-

4. High-frequency gluing process

The time required for gluing is shorter (within one minute) compared to natural curing methods. As the processes are not interrupted, a longer time can be used for the chamfering process.

The time required for gluing is shorter (within one minute) compared to natural curing methods. As the processes are not interrupted, a longer time can be used for the chamfering process.

-

5. Chamfering process

Customers are required to perform the cutting of only a limited number of summits. Furthermore, since no gaps are created between wood plates, puttying will not be necessary.

-

6. Painting process

-

7. Completion